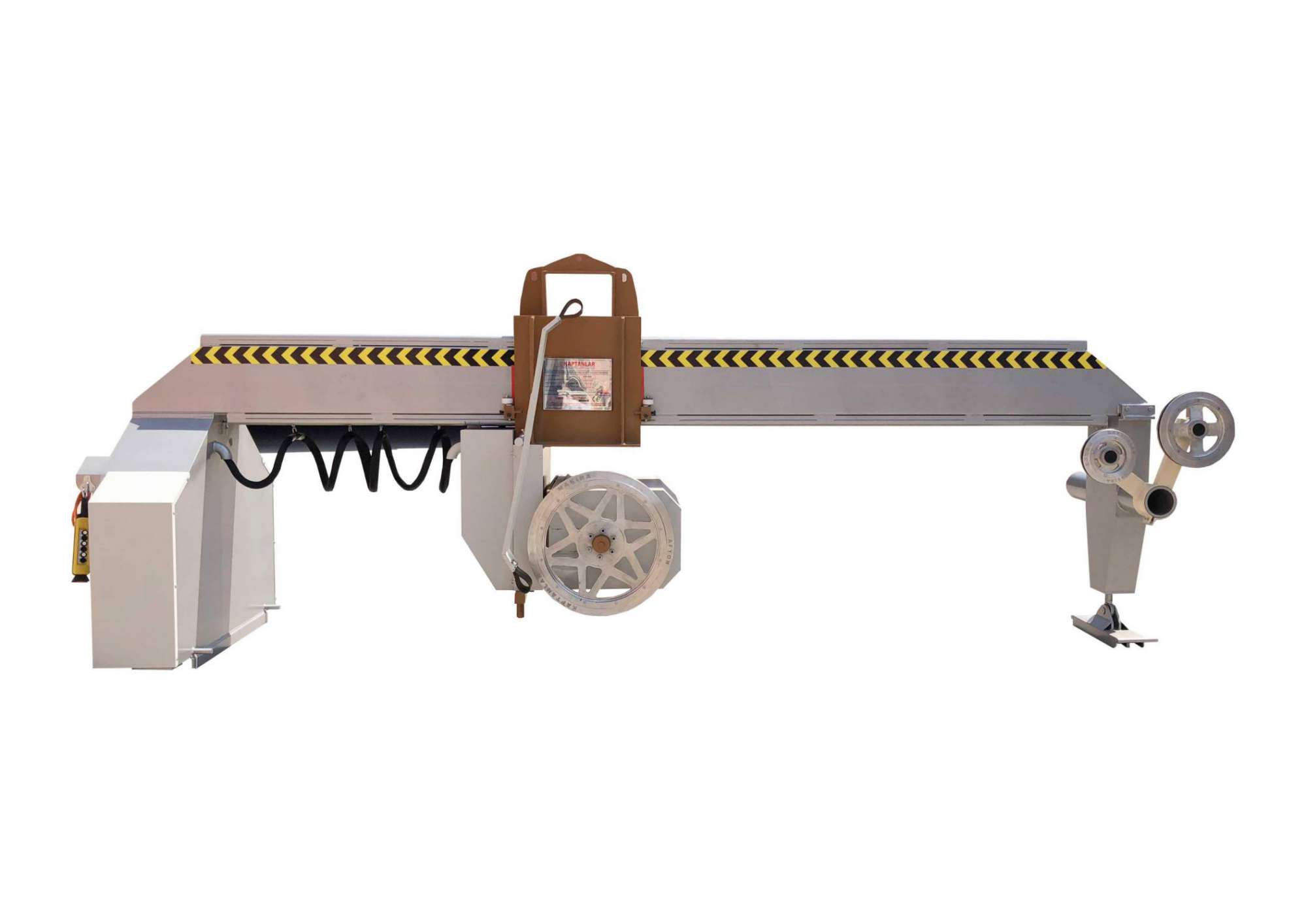

ETK 80S - Diamond Wire Cutting

ETK 80S ELECTRIC AUTOMATIC WALKING SERIES DIAMOND WIRE BLOCK CUTTING MACHINE

It is a block cutting machine with diamond wire that can cut at the desired angle. It has the features of a chassis designed to move back and forth on a detachable rail block and containing the necessary elements for the structure, a travel motor positioned at the bottom of the chassis and allowing the structure to move, a motor that can move the main pulley with a shaft, a hydraulic coupling positioned between the motor and the shaft, a body that surrounds and protects the internal parts of the machine, which provides a gearbox movement that regulates the movement between the shaft and the main pulley, an electrical panel providing the controls of a positioned machine is connected to the main pulley with the guide pulley arm, at least one auxiliary pulley connected around the main pulley in a way that allows the wire connected to the main pulley to pass over the main pulley and auxiliary pulley. The machine, which can perform serial cutting due to its features, with a casing positioned at the back of the chassis and a cable carrier positioned in line with the casing at the front of the chassis. The diamond wire is automatically tightened by the travel motors during cutting.It is rotated with the help of the main and guidance flywheels and enables it to cut and separate the block marble. Thus, the cutting process is completed. In the serial block cutting machine with electric diamond wire, water is sent to the cutting area with hoses during the cutting process and control can be achieved with the help of a valve. Thanks to the water, the cutting tool (Diamond Wire) is prevented from overheating and the marble dust is removed from the cutting area.

Technical Specifications

|

Motor Type

|

Electric, 55 kW, 80 hp, 380 V, 1500 rpm |

| Walking System | 1.5 kW, 2 hp, 380 V, 1500 rpm, Automatic Adjustable Motor |

| Machine Start-Up | Star-Delta Starter and Hydraulic Torque Coupling Grip |

| Wire to be used | Diamond |

| Cutting Speed | 10-25 m² / h |

| Wire Rotation Capacity | 100 – 150 m |

| Working Angle | 360° All positions |

| Total Rail Lenght | 6m, 3×2m |

| Water Need | 500 lt/h |

| Main Flywheel Diameter | 80 cm |

| Direction Flywheel Diameter | 30 cm |

| Total Weight | 1600 kg |

| Dimensions (Length × Wdith × Height) | 2.8 m ×1.7m × 1.2 m |

User's Guide

Product Videos